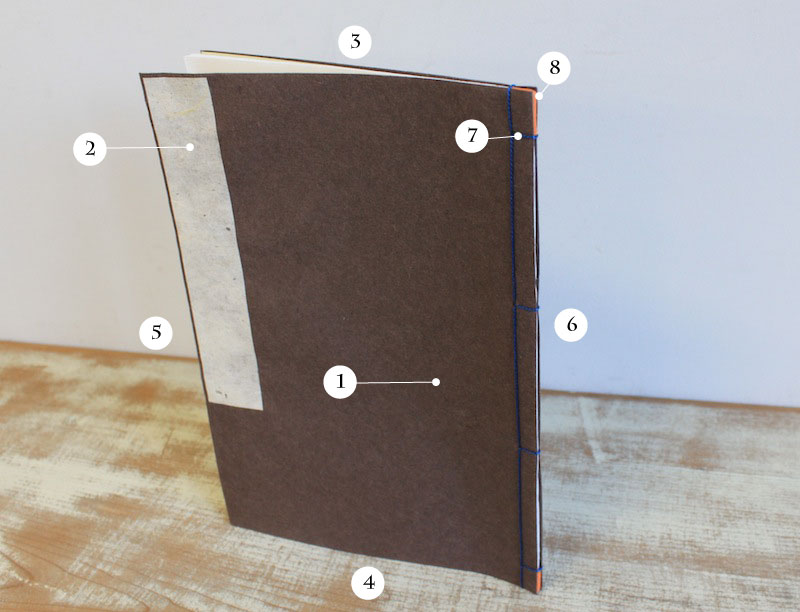

Wahon (Japanese book)

Wahon, or Japanese books, is a general term for books made from Japanese paper using traditional Japanese binding techniques. These books come in various types and shapes, with the most common styles including 4-hole binding, folded-page books, Retsujosou (列帖装), Yamato-toji (大和綴), scrolls, handscrolls, and Edo-period account and receipt books used for ledgers.

The textblock in Japanese books is typically formed using a basic double-leaved binding method, where pages are folded in half with the folded edge placed at the fore edge. This approach exposes only the front side of each sheet of paper.

Special storage cases are often used for Japanese books, such as the chitsu (a folding case) and the meotobako (a clamshell box), designed to protect and preserve these unique volumes.

Glossary of Specialized Terms for Japanese Books [Japanese-English]

Chitsu (Japanese box)

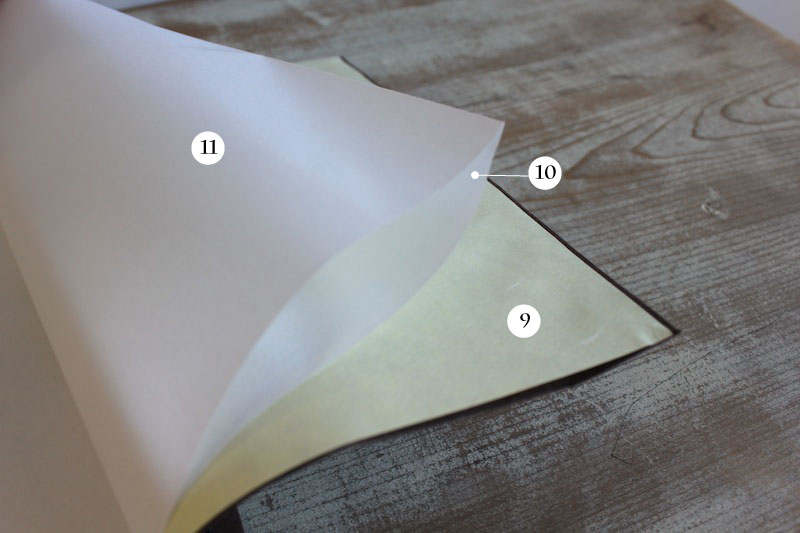

Washi (Japanese paper)

The origins of paper technology in Japan are believed to date back to 610 AD during the reign of Empress Suiko. It was introduced to Japan by Damjing from the Korean kingdom of Goguryeo and later refined by figures such as Shoutoku Taishi to create what is now known as Japanese paper, or washi. Washi is primarily made from the bast fibers—the soft inner bark beneath the outer bark—of plants such as the paper mulberry, mitsumata, and Diplomorpha sikokiana, a species of flowering plant.

The process of making washi involves stewing the fibers with wood ash to prepare them before mixing them with a starchy substance called neri, derived from the sunset hibiscus. The mixture is then spread onto a screen to extract the pulp and form sheets of paper.

One of the key components of plant material, lignin, has low water affinity and, if left in the paper, can weaken and oxidize it over time. Japanese paper naturally contains low levels of lignin, and the use of wood ash helps remove any remaining lignin, softening the fibers without damaging them. This results in a paper with a high degree of polymerization. Additionally, the bast fibers in washi are longer and more durable than wood pulp fibers, giving the paper excellent preservative qualities.

However, in recent years, the market has seen an increase in Japanese paper of lower quality. Some of this paper is imported or produced using excessively bleached pulp, or by processes like boiling or sizing, which compromise its preservative properties. As a result, not all washi available today maintains the traditional high standards of quality.

Note: There are differing opinions about the history of washi. Please consider this as one possible explanation.